Introduction to Automation in Logistics and Supply Chain Management

Automation in logistics and supply chain management refers to the use of advanced technologies to optimize and streamline processes. Key technologies driving this transformation include robotics, artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These innovations are reshaping the landscape of logistics and supply chains, enabling more efficient operations, reducing human error, and cutting costs.

Historically, logistics and supply chain management relied heavily on manual labor and rudimentary tracking systems. Over the decades, technological advancements have progressively integrated into these processes, starting from the introduction of barcoding and electronic data interchange (EDI) in the late 20th century. These early innovations laid the groundwork for more sophisticated solutions, such as warehouse management systems (WMS) and transportation management systems (TMS), which have become integral to modern supply chains.

Today, robotics and automation are revolutionizing how goods are stored, handled, and transported. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are increasingly common in warehouses, performing tasks such as picking, sorting, and palletizing with precision and efficiency. AI and machine learning algorithms are being used to predict demand, optimize inventory levels, and enhance decision-making processes. Meanwhile, IoT devices provide real-time visibility into the movement and condition of goods, enabling better tracking and monitoring throughout the supply chain.

The importance of automation in logistics cannot be overstated. It offers numerous benefits, including increased speed and accuracy, enhanced scalability, and the ability to operate around the clock without the limitations of human labor. Automation also plays a crucial role in improving safety by reducing the likelihood of accidents and injuries. Furthermore, with the growing complexity and scale of global supply chains, automation helps companies stay competitive by enabling them to respond quickly to market changes and customer demands.

This evolving landscape underscores the need for businesses to embrace automation not just as a trend, but as a critical strategy for long-term success. As we delve deeper into specific applications and the broader impact of these technologies, it becomes clear that the future of logistics and supply chain management is inextricably linked to the continued advancement and integration of automation.

Key Technologies Driving Automation

Automation in logistics and supply chain management is largely driven by a suite of advanced technologies that streamline operations, enhance efficiency, and reduce human error. One of the most prominent technologies in this field is robotics. In warehouses, robots are utilized for tasks such as picking and packing, sorting, and even inventory management. These robots are equipped with sensors and cameras, enabling them to navigate complex environments and perform tasks with high precision. Companies like Amazon and Walmart have successfully implemented robotics in their warehouses, significantly reducing processing times and operational costs.

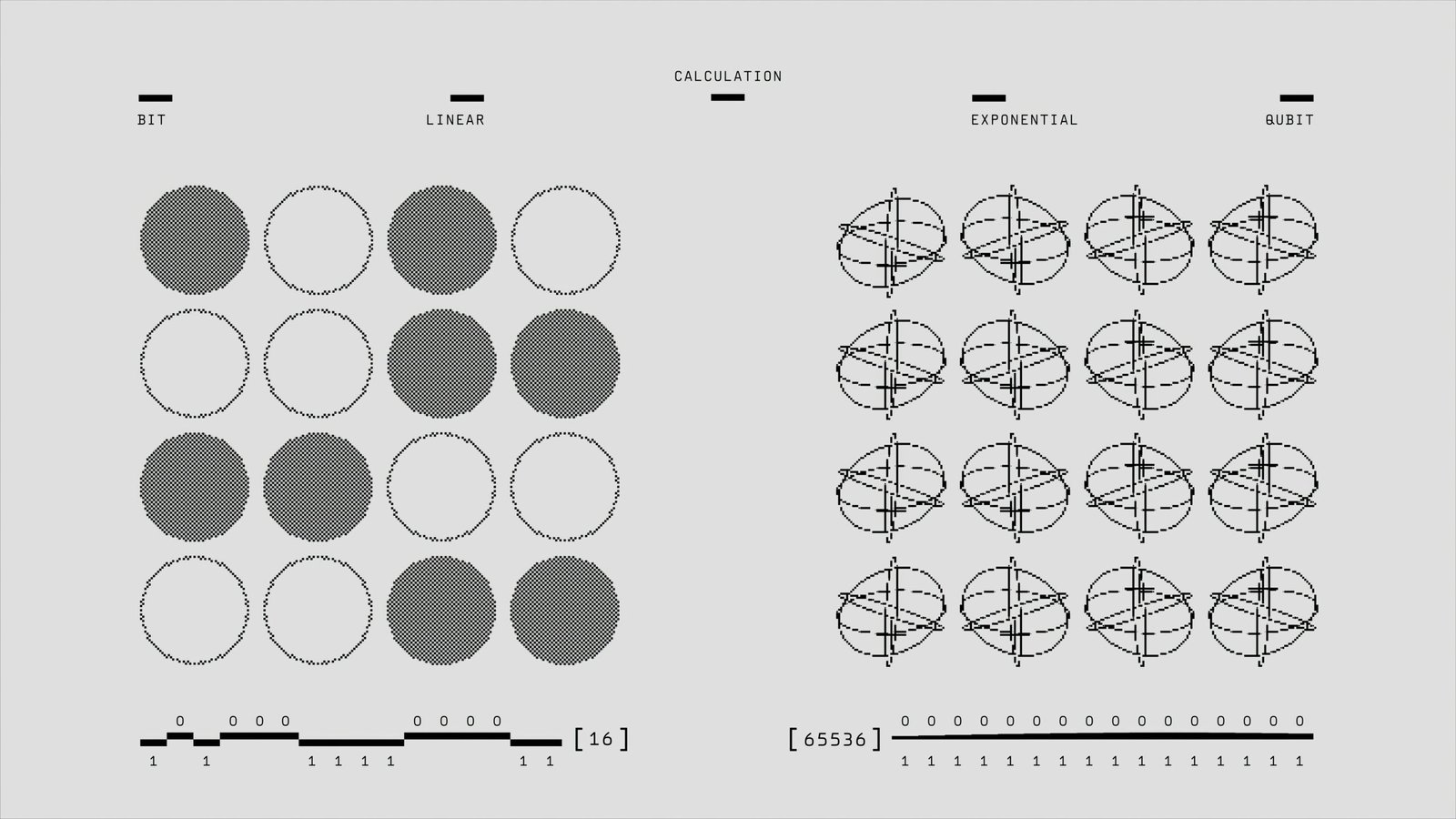

Another critical technology transforming logistics is artificial intelligence (AI) and machine learning. AI algorithms are employed to optimize various aspects of supply chain management, including route planning and inventory management. Machine learning models analyze vast amounts of data to predict demand, optimize stock levels, and plan the most efficient delivery routes. For instance, DHL uses AI to enhance its logistics operations by predicting shipment volumes and optimizing delivery schedules, ultimately improving customer satisfaction and reducing costs.

The Internet of Things (IoT) also plays a vital role in driving automation in logistics. IoT devices, such as sensors and GPS trackers, enable real-time tracking of goods and assets, providing valuable data on the location, condition, and status of shipments. This real-time visibility allows companies to monitor their supply chains more effectively, quickly address any issues, and enhance overall operational efficiency. A notable example is Maersk, which uses IoT technology to track its containers globally, ensuring timely deliveries and reducing losses due to damaged or misplaced goods.

Blockchain technology is another innovation making waves in supply chain automation. Blockchain provides a secure, transparent, and immutable ledger for recording transactions, making it ideal for tracking goods and verifying authenticity throughout the supply chain. By leveraging blockchain, companies can enhance traceability, reduce fraud, and improve compliance with regulatory requirements. IBM and Walmart’s collaboration on a blockchain-based food traceability system is a prime example, ensuring food safety and transparency from farm to table.

Incorporating these technologies into logistics and supply chain management not only enhances operational efficiency but also provides a competitive edge in an increasingly complex and fast-paced market. Companies that effectively implement robotics, AI, IoT, and blockchain are likely to lead the industry, setting new standards for automation and innovation.

Benefits and Challenges of Automation

The integration of automation in logistics and supply chain management has revolutionized the industry, presenting numerous advantages that drive operational performance. One of the most significant benefits is the increased efficiency it brings. Automated systems can handle repetitive and time-consuming tasks more quickly and accurately than human workers, reducing the time required for processes such as inventory management, order fulfillment, and transportation. This, in turn, leads to reduced operational costs, as companies can streamline their operations and reduce labor expenses.

Another notable advantage is the improvement in accuracy. Automation minimizes the risk of human error, ensuring that tasks are performed consistently and correctly. This is particularly crucial in logistics, where precise inventory tracking and order accuracy are essential for maintaining customer satisfaction. Moreover, automated systems can analyze vast amounts of data in real-time, providing insights that help companies make informed decisions and optimize their supply chain processes.

Enhanced customer satisfaction is another key benefit of automation. Faster and more accurate order processing leads to shorter delivery times and fewer errors, which directly contributes to a better customer experience. Additionally, automated systems can provide real-time updates on order status, further enhancing transparency and trust between companies and their customers.

However, the implementation of automation is not without its challenges. One of the primary obstacles is the high initial investment cost. Setting up automated systems requires substantial capital expenditure on technology, infrastructure, and training. This can be a significant barrier for small and medium-sized enterprises. Additionally, automation introduces cybersecurity threats, as connected systems are susceptible to hacking and data breaches, necessitating robust security measures.

Furthermore, the management and maintenance of automated systems require skilled labor. Companies must invest in training their workforce to handle new technologies and troubleshoot issues when they arise. This can lead to a skills gap, where the existing workforce may not be adequately prepared to manage advanced automated systems.

To maximize the benefits of automation while mitigating its challenges, companies should adopt a strategic approach. This involves conducting thorough cost-benefit analyses, investing in cybersecurity measures, and providing continuous training for their employees. By doing so, organizations can leverage the advantages of automation to enhance their logistics and supply chain management while addressing potential downsides effectively.

Future Trends and Innovations

The landscape of logistics and supply chain management is poised for transformative changes driven by automation. Among the most promising advancements are autonomous vehicles for delivery, which are set to redefine last-mile logistics. These vehicles, equipped with sophisticated AI systems, can operate without human intervention, significantly reducing delivery times and costs while enhancing efficiency. Companies like Amazon and UPS are already piloting such technologies, hinting at a future where human drivers might become a rarity.

Drone technology is another groundbreaking innovation making waves in inventory management. Drones equipped with high-resolution cameras and sensors can perform real-time stock checks in massive warehouses, ensuring more accurate inventory counts and reducing the time spent on manual audits. They can also navigate hard-to-reach areas, providing a level of precision and efficiency that traditional methods cannot match. This technology is not only streamlining operations but also minimizing human error and enhancing overall productivity.

Advanced predictive analytics are revolutionizing demand forecasting, enabling companies to make more informed decisions about inventory levels, procurement, and distribution. By leveraging big data and machine learning algorithms, businesses can now predict consumer demand with unprecedented accuracy, thereby reducing waste and optimizing supply chain processes. This capability is crucial in an era where consumer preferences are rapidly changing, and agility is key to maintaining a competitive edge.

Sustainability is increasingly becoming a focal point in future automation efforts. Green technologies and eco-friendly practices are being integrated to reduce the carbon footprint of logistics operations. For instance, electric and hydrogen-powered vehicles are being developed to replace traditional fossil-fuel-based transportation methods. Similarly, renewable energy sources are being harnessed to power automated warehouses, aligning operational efficiency with environmental responsibility.

The next decade promises even more evolution in the logistics and supply chain industry. As technological advancements continue to emerge, so will the economic and regulatory landscapes shift. Businesses must stay agile, adopting new innovations while complying with evolving regulations. The convergence of these factors will shape a future where logistics and supply chain management are more efficient, sustainable, and responsive to global demands.