Introduction to Collaborative Robots

Collaborative robots, commonly known as ‘cobots,’ represent a transformative shift in the field of robotics. Unlike traditional industrial robots, which are typically confined to isolated environments due to safety concerns, cobots are designed to work alongside human operators in a shared workspace. This key distinction has positioned cobots as pivotal assets in modern automation, fostering a collaborative synergy between human dexterity and robotic precision.

The concept of cobots is relatively recent in the historical timeline of robotics. The earliest forms of industrial robots emerged in the mid-20th century, geared towards repetitive and hazardous tasks in manufacturing. Over time, advancements in technology and a deeper understanding of human-robot interaction led to the development of cobots. These robots are equipped with advanced sensors, artificial intelligence, and safety features that enable them to operate safely in proximity to humans.

The rise in popularity of collaborative robots is underpinned by several market trends and statistics. According to recent market analysis, the global cobot market is projected to grow at a compound annual growth rate (CAGR) of over 30% in the coming years. This surge is driven by multiple factors including the need for flexible automation solutions, labor shortages, and the increasing emphasis on workplace safety. Industries such as automotive, electronics, and logistics are leading the adoption of cobots, with small and medium-sized enterprises (SMEs) also recognizing their potential to enhance productivity and efficiency.

In summary, the evolution of robotics towards collaborative models marks a significant milestone in industrial automation. Cobots, with their ability to seamlessly integrate into human-centric environments, offer a compelling solution to the dynamic needs of modern industries. The ongoing advancements in cobot technology and their growing adoption across various sectors highlight the transformative impact of these innovative machines on the future of work.

Applications and Use Cases

Collaborative robots, commonly known as cobots, have become pivotal across various industries, significantly transforming the landscape of traditional operations. In the manufacturing sector, cobots are increasingly being integrated into assembly lines where they handle tasks such as welding, painting, and machine tending. Their ability to work alongside human workers enhances productivity and precision, effectively reducing error rates and improving overall efficiency. For example, in automotive manufacturing, cobots assist in assembling complex components, ensuring consistency and enhancing throughput.

In the healthcare industry, cobots play a crucial role in performing delicate and repetitive tasks, such as assisting in surgeries, delivering medications, and handling laboratory specimens. This integration not only alleviates the workload on medical professionals but also ensures high precision, reducing the margin for human error. A notable case study is the deployment of the da Vinci Surgical System, a robotic platform that allows surgeons to perform minimally invasive procedures with enhanced accuracy and control.

The agriculture sector has also seen significant benefits from the use of cobots. These robots assist in tasks such as planting, harvesting, and monitoring crop health. Equipped with advanced sensors and AI capabilities, agricultural cobots can analyze soil conditions, detect pests, and optimize farming practices, ultimately leading to higher yields and sustainable farming. An example of this is the use of cobots in fruit picking, where their ability to operate tirelessly ensures timely and efficient harvesting.

In the service sector, cobots are enhancing customer experiences by performing tasks that require high precision and consistency. In retail, cobots assist in inventory management, shelf stocking, and customer service. The hospitality industry leverages cobots for room service and cleaning tasks, ensuring a seamless and efficient service delivery. A case in point is the use of robotic baristas that prepare coffee with consistent quality, offering a unique and efficient customer experience.

Looking ahead, the potential applications of cobots are vast and varied. As technology advances, we can expect cobots to take on more complex tasks, further expanding their role in different industries. From intricate surgical procedures to sophisticated agricultural analysis, the future of cobots is poised to revolutionize the way we work, making operations safer, more efficient, and highly precise.

Advantages and Challenges of Cobots

Collaborative robots, or cobots, present numerous advantages that are revolutionizing various industries. One of the primary benefits of cobots is increased efficiency. By automating repetitive and mundane tasks, cobots allow human workers to focus on more complex and creative activities. This division of labor can significantly boost productivity and streamline operations.

Improved safety is another critical advantage of cobots. Designed to work alongside humans, cobots are equipped with advanced sensors and safety features to prevent accidents and injuries. This capability reduces workplace hazards, ensuring a safer environment for employees. Additionally, cobots can handle tasks that may be dangerous for humans, such as working with hazardous materials or in extreme conditions, further enhancing workplace safety.

Cost-effectiveness is a significant factor driving the adoption of cobots. Compared to traditional industrial robots, cobots are generally more affordable and easier to implement. Their flexibility allows them to be used in various applications, reducing the need for multiple specialized machines. Businesses can achieve a faster return on investment thanks to the lower upfront costs and the efficiency gains provided by cobots.

However, the integration of cobots into the workplace is not without challenges. Technical constraints can limit their capabilities in certain scenarios, requiring ongoing advancements in robotics technology to overcome these limitations. Integration issues also pose a challenge, as cobots must be seamlessly incorporated into existing workflows and systems, which can be complex and time-consuming.

Concerns about job displacement are common when discussing automation. While cobots are designed to complement rather than replace human workers, there is still apprehension about potential job losses. It is crucial for businesses to balance the use of cobots with initiatives that support workforce transition and upskilling, ensuring that employees can adapt to the changing job landscape.

Human-robot interaction is another area of concern. Effective collaboration requires that cobots be intuitive and user-friendly, enabling workers to interact with them effortlessly. Designing cobots that can understand and respond to human cues is essential for fostering a harmonious and productive working relationship.

By weighing these pros and cons, it becomes evident that while cobots offer substantial benefits, careful consideration and planning are necessary to address the challenges they present. This balanced understanding allows businesses to harness the potential of cobots effectively while mitigating associated risks.

Future Outlook and Trends

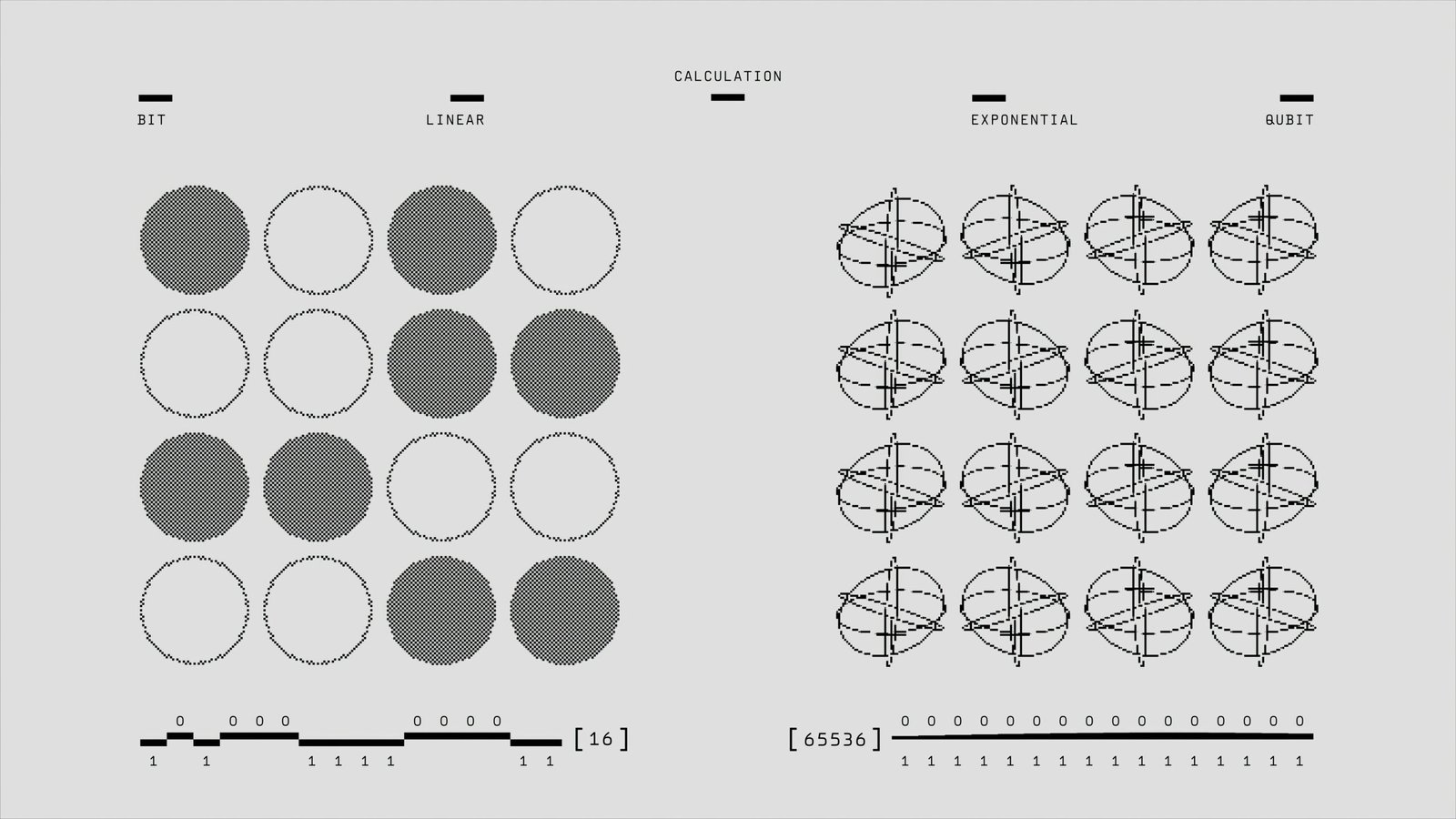

The future of collaborative robots, or cobots, appears exceptionally promising, driven by cutting-edge advancements in artificial intelligence (AI) and machine learning (ML). These technologies are set to enhance the cognitive capabilities of cobots, enabling them to perform more complex tasks with greater precision and autonomy. With AI and ML, cobots will be able to learn from their environments and improve their performance over time, offering a significant leap in efficiency and functionality.

Another key area of development is the human-robot interface design. Future cobots will likely feature more intuitive and user-friendly interfaces, facilitating seamless interaction between humans and machines. Innovations such as voice recognition, gesture control, and advanced touchscreens will make it easier for operators to control and communicate with cobots, thereby enhancing productivity and safety.

As cobots become more autonomous, the regulatory landscape will need to adapt accordingly. There will be a growing emphasis on establishing robust standards for safety and interoperability to ensure that these machines can operate reliably alongside human workers. Regulatory bodies are expected to develop comprehensive frameworks that address the unique challenges posed by cobots, including their integration into various industries and compliance with existing safety standards.

In the context of Industry 4.0, cobots will play a pivotal role in driving the next wave of industrial transformation. Their ability to work collaboratively with human counterparts makes them ideal for a wide range of applications, from manufacturing and logistics to healthcare and service industries. Industry experts predict that cobots will significantly influence production lines, supply chains, and customer service operations, leading to more efficient and adaptable systems.

Insights from industry leaders suggest that as cobots evolve, they will not only enhance operational efficiency but also contribute to a safer and more flexible work environment. By taking on repetitive, dangerous, or monotonous tasks, cobots will allow human workers to focus on more strategic and creative activities. This symbiotic relationship between humans and cobots will be instrumental in shaping the future of various sectors, driving innovation, and fostering economic growth.