Introduction to Biomanufacturing

Biomanufacturing represents a transformative approach to production, fundamentally differing from traditional manufacturing methods. It leverages biological systems, such as living cells or their components, to create industrially valuable products. This innovative process involves the use of microorganisms, plant cells, or mammalian cells to generate a wide range of outputs, from pharmaceuticals to biofuels and even newer materials. As opposed to traditional methods that often rely on chemical processes or mechanical assembly, biomanufacturing harnesses the intrinsic abilities of biological entities to produce complex compounds efficiently and sustainably.

The foundation of biomanufacturing lies in its ability to utilize the natural biological processes for synthesis and assembly. A key principle is the harnessing of metabolic pathways within cells to produce desired substances. For instance, yeast cells can be engineered to produce insulin, while bacteria can be tailored to create bio-based polymers. These cells serve as miniature production factories, offering efficiency and low environmental impact due to their reliance on renewable resources and biodegradability of the products.

Historically, the roots of biomanufacturing can be traced back to ancient times when humans first initiated fermentation processes to produce bread, beer, and cheese. However, the modern era of biomanufacturing began in earnest during the 20th century with advances in molecular biology and genetic engineering. The advent of recombinant DNA technology in the 1970s marked a significant milestone, enabling the precise manipulation of genetic material to produce specific proteins and enzymes. This laid the groundwork for the burgeoning field of biomanufacturing we know today.

The significance of biomanufacturing spans multiple industries, making profound impacts globally. In the pharmaceutical sector, it has revolutionized the production of drugs, enabling the large-scale synthesis of complex biologics and vaccines. In agriculture, biomanufacturing is paving the way for the development of bio-based fertilizers and pest control solutions that are environmentally friendly. Meanwhile, in the realm of materials science, biomanufacturing is fostering the creation of sustainable biomaterials and bioplastics, which can potentially substitute petrochemical-based products. Thus, biomanufacturing holds the promise of addressing critical challenges, from medical needs to environmental sustainability, making it a cornerstone of modern and future production technologies.

Technological Advances and Innovations

The field of biomanufacturing has witnessed significant technological advancements, revolutionizing the production landscape. At the forefront of these developments is synthetic biology, which has paved the way for the creation and manipulation of biological systems. Synthetic biology enables the design of microorganisms with bespoke genetic circuits, optimizing the production of desired compounds such as pharmaceuticals, biofuels, and specialty chemicals. This branch of science has expanded the toolkit available for biomanufacturing, greatly enhancing precision and scalability.

Another groundbreaking innovation is CRISPR gene editing, a technology that allows for precise alterations to DNA. CRISPR’s ability to edit genes with high accuracy has enabled the development of engineered organisms that can produce complex biological molecules more efficiently. This has not only streamlined the biomanufacturing processes but also significantly reduced the time and cost involved in creating genetically modified organisms (GMOs). By harnessing CRISPR, biomanufacturers can now engineer microorganisms to produce higher yields of targeted products, thus optimizing production output.

Advanced fermentation techniques have also played a crucial role in propelling biomanufacturing forward. These techniques have improved the efficiency of converting raw materials into final products through fermentation processes. Innovations such as continuous fermentation and the use of genetically engineered strains have substantially increased productivity, enabling manufacturers to meet growing demand while maintaining quality and consistency.

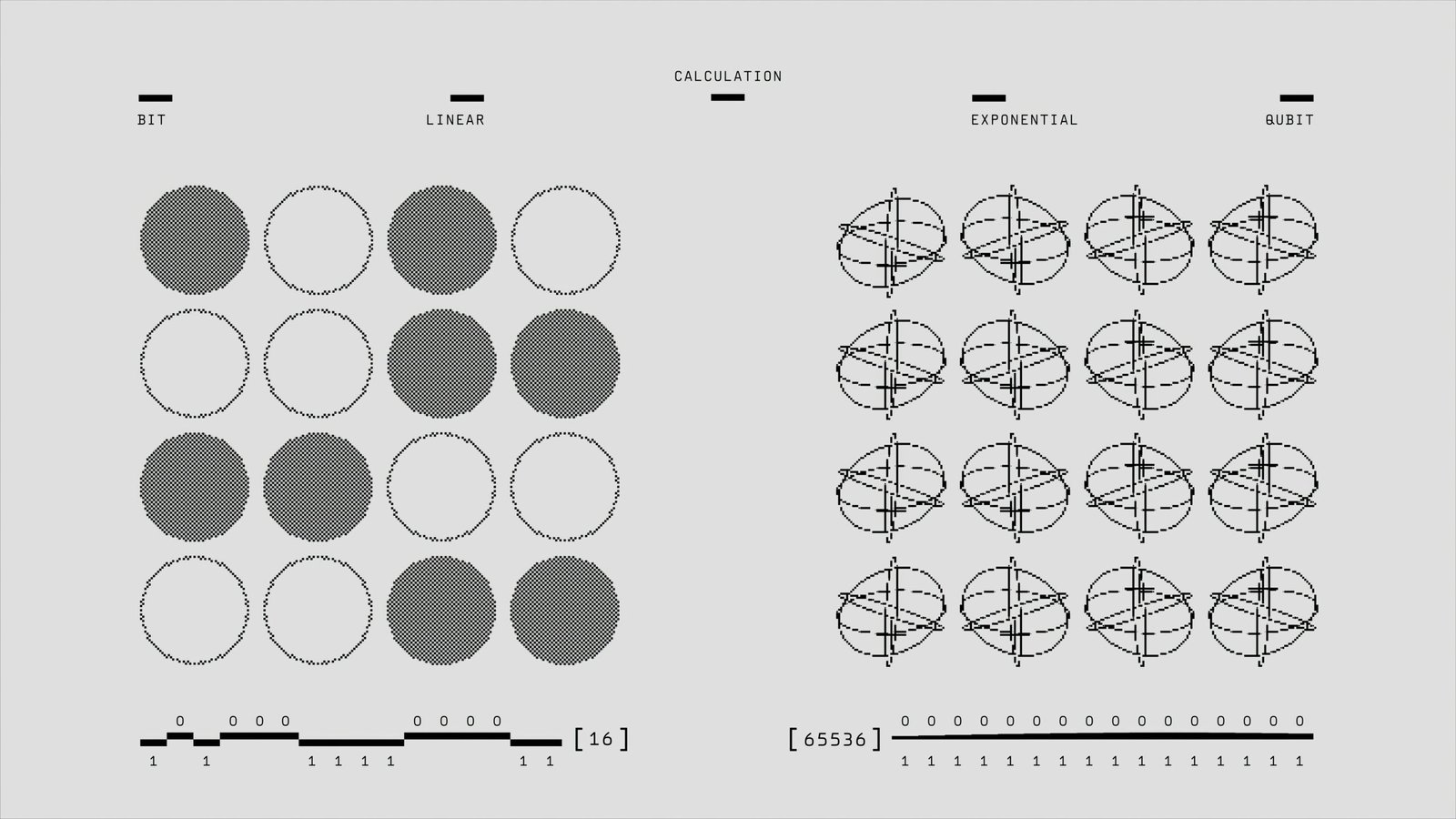

In addition to these biological advancements, automation, artificial intelligence (AI), and machine learning have transformed biomanufacturing operations. Automation systems streamline routine tasks, reduce human error, and increase production speed. AI and machine learning algorithms analyze vast amounts of data to optimize production conditions and predict potential issues before they arise. These technologies have collectively enhanced the decision-making process in biomanufacturing, leading to more informed and efficient operations.

Overall, these technological innovations have broadened the horizons of biomanufacturing, allowing for the production of a diverse array of products. From sustainable biofuels to lifesaving drugs, the integration of cutting-edge technologies has fundamentally reshaped what can be achieved through biomanufacturing, heralding a new era of production capabilities.

Applications and Benefits

Biomanufacturing is revolutionizing numerous sectors, offering innovative solutions that enhance both economic and environmental sustainability. One of the most significant applications is in the production of biopharmaceuticals like insulin, vaccines, and monoclonal antibodies. These biopharmaceuticals, produced using genetically engineered cells, often possess superior efficacy and fewer side effects compared to traditional pharmaceuticals. For instance, the breakthrough in producing human insulin through recombinant DNA technology has transformed diabetes treatment, making it more accessible and cost-effective.

Apart from healthcare, the energy sector also benefits from biomanufacturing. Biofuels, such as bioethanol and biodiesel, are derived from biological materials through fermentation processes. Unlike fossil fuels, biofuels produce fewer greenhouse gas emissions, contributing to a reduction in global carbon footprint. Companies like Amyris and Neste are leading in this domain, demonstrating how biomanufactured biofuels can power vehicles and even aircraft engines more sustainably.

The development of sustainable materials is another crucial application. Biomanufacturing enables the creation of materials like biopolymers and cellulose-based products, which are both durable and biodegradable. Organizations like DuPont have pioneered using corn glucose to produce a biopolymer known as Sorona, which is utilized in textiles and carpeting. This innovation not only reduces reliance on petrochemicals but also minimizes waste, promoting a circular economy.

Furthermore, biomanufacturing aids in producing biodegradable plastics, providing a viable alternative to conventional plastics that are often a major source of environmental pollution. Companies such as NatureWorks are making significant strides by producing polylactic acid (PLA) from fermented plant starch, which can be composted industrially, reducing plastic waste and its detrimental impact on marine and terrestrial ecosystems.

The benefits of biomanufacturing extend beyond environmental sustainability. It often involves streamlined and cost-effective production processes. For instance, microbial fermentation can yield high product quantities within shorter timeframes compared to traditional methods. This efficiency contributes to reduced operational costs and improved product consistency and quality. The biotechnology firm Ginkgo Bioworks exemplifies this by using synthetic biology to program microorganisms for manufacturing a wide array of consumer products, showcasing the versatility and economic viability of biomanufacturing.

In essence, biomanufacturing signifies a progressive shift towards more sustainable, cost-efficient, and high-quality production methods across various industries, underscoring its potential as the future of production.

Biomanufacturing, while promising, confronts several notable challenges. Chief among these are technical hurdles, particularly in ensuring consistent product quality and yield. The complexity of biological systems presents a detailed technical landscape where fine-tuning every parameter is crucial. Additionally, scalability poses a significant issue—processes that work effectively at a laboratory scale often face unpredicted complications when scaled up to industrial levels. Achieving economic feasibility is another critical challenge, as the cost of raw materials and the complexity of biomanufacturing processes frequently result in higher expenses compared to traditional manufacturing methods.

Moreover, regulatory considerations add another layer of complexity. Regulatory bodies demand rigorous testing and validation procedures to ensure safety, which can be both time-consuming and costly. The standardization of biomanufacturing protocols is still evolving, compounding the industry’s challenges.

Ongoing research and development efforts are crucial to overcoming these barriers. Innovations in synthetic biology aim to streamline the process, making it more predictable and less costly. Advances in process automation and digitalization are enabling better monitoring and control, addressing scalability issues. Researchers are also developing novel bioreactors and fermentation technologies that could increase efficiency and reduce costs. Interdisciplinary collaboration remains vital, bridging gaps between biology, engineering, and computer science to foster more holistic solutions.

In terms of future prospects, biomanufacturing is poised for transformative breakthroughs. The growing field of bioinformatics and computational biology is expected to play a crucial role in optimizing biomanufacturing processes. There is also significant potential for integrating artificial intelligence and machine learning to predict and enhance outcomes. Furthermore, government policies and investments can significantly shape the future landscape by funding cutting-edge research and creating favorable regulatory environments.

Ultimately, biomanufacturing holds the promise of revolutionizing production across various industries. As the realm of biomanufacturing evolves, it is envisioned that it will substantially contribute to more sustainable and efficient production methods, reducing the environmental footprint and pushing the boundaries of what is feasible in production technologies.