Introduction to 3D Printing in Space

3D printing, also known as additive manufacturing, is a revolutionary technology that constructs objects layer by layer from digital models. Originally used for rapid prototyping, it has evolved to create intricate and durable structures across various industries. Its rise as a critical tool in space exploration is reshaping how we think about building in environments far from Earth.

In space, traditional construction methods face insurmountable challenges. The microgravity environment, for one, complicates the use of conventional tools and techniques designed for Earth’s gravitational forces. Additionally, the presence of cosmic radiation and extreme temperature fluctuations necessitates materials and methods resilient to such harsh conditions.

3D printing in space offers viable solutions to these unique challenges. By enabling the construction of custom parts and structures directly in space, it reduces the need for pre-fabricated supplies, significantly cutting down launch costs and payload weights. Astronauts can produce tools, repair kits, and even habitat components on-demand, using materials sourced either from Earth or potentially harvested from extraterrestrial bodies.

The technology’s adaptability and precision make it ideal for space missions where resources are limited and resupply missions are both costly and logistically demanding. Advances in 3D printing have seen the development of specialized printers, capable of functioning under microgravity conditions, and materials specifically engineered to withstand the rigors of space.

Understanding the basic principles of 3D printing and recognizing its transformative applications unlock a new frontier for space exploration. It serves not only to enhance current missions but also to lay the groundwork for sustained human presence on the Moon, Mars, and beyond. The subsequent sections will delve deeper into the specific applications and breakthroughs in 3D printing technology that are paving the way towards this bold, off-Earth future.

3D printing technology has already made significant strides in space missions, demonstrating its immense potential and practical applications. Various space agencies, such as NASA and the European Space Agency (ESA), alongside private companies like SpaceX and Blue Origin, have begun to embrace this innovative approach to manufacturing in space.

One of the most notable applications of 3D printing in space is aboard the International Space Station (ISS). Here, astronauts have successfully 3D-printed a range of tools and spare parts, which not only reduces dependency on Earth-based supplies but also minimizes mission risk and cost. This capability allows for the immediate production of essential components, greatly enhancing the efficiency and self-sufficiency of long-term space missions.

In addition to tools and parts, 3D printing is also being explored for constructing habitats on the Moon and Mars. Concepts for lunar and Martian missions involve using this technology to build habitation structures using local materials, such as regolith. NASA’s Artemis program, for example, aims to utilize regolith-based 3D printing techniques to create durable and cost-effective habitats on the Moon. Such innovations could be crucial for establishing sustainable human presence on other celestial bodies.

Private companies are also investing heavily in 3D printing technology for space applications. SpaceX and Blue Origin, for instance, have explored its potential to construct rocket components more efficiently, thereby reducing production time and costs. By integrating 3D printing into their manufacturing processes, these companies can create complex parts that would be difficult or impossible to assemble with traditional methods.

Furthermore, ESA’s Project MELT (Manufacturing of Experimental Layer Technology) aims to develop a 3D printer capable of using metal powders to produce spacecraft components. This project underscores the diverse applications of 3D printing in space, from simple tools to highly advanced manufacturing technologies.

Overall, 3D printing is becoming a defining technology in space exploration, offering significant benefits in terms of cost, efficiency, and innovation. As these applications continue to evolve, they hold the promise of revolutionizing how we build and sustain future space missions.

Advantages and Challenges of 3D Printing in Space

The rise of 3D printing in space promises a transformative shift in how we approach off-Earth manufacturing, offering myriad benefits. One of the primary advantages is the significant reduction in launch costs. By manufacturing objects in space, the necessity to transport bulky items from Earth is diminished, conserving valuable payload space and reducing overall mission expenses.

On-demand manufacturing capabilities further enhance mission efficiency. Crews can produce necessary tools, components, or even habitats as required, avoiding delays associated with waiting for supplies from Earth. This on-site production minimizes reliance on Earth-based resources, fostering a self-sustaining environment vital for long-term space missions and extraterrestrial colonization.

Leveraging in-situ resources, such as lunar regolith or Martian soil, is another groundbreaking advantage. Utilizing locally available materials for construction can drastically reduce the cost and energy consumption associated with transporting building materials from Earth. This approach paves the way for innovative uses of extraterrestrial geology, contributing to sustainable operations on the moon, Mars, and beyond.

Despite these promising benefits, 3D printing in space also faces substantial challenges. The harsh conditions of space, including extreme temperatures and radiation, pose significant obstacles to both machinery and materials. Printers must endure and function reliably in this unforgiving environment to ensure mission success.

Material limitations also present a complex hurdle. Not all terrestrial materials are suitable for use in space’s unique environment, requiring the development and testing of new composites that can withstand space-specific stresses. Quality control is another critical concern, as even minor imperfections in printed objects can lead to mission-critical failures.

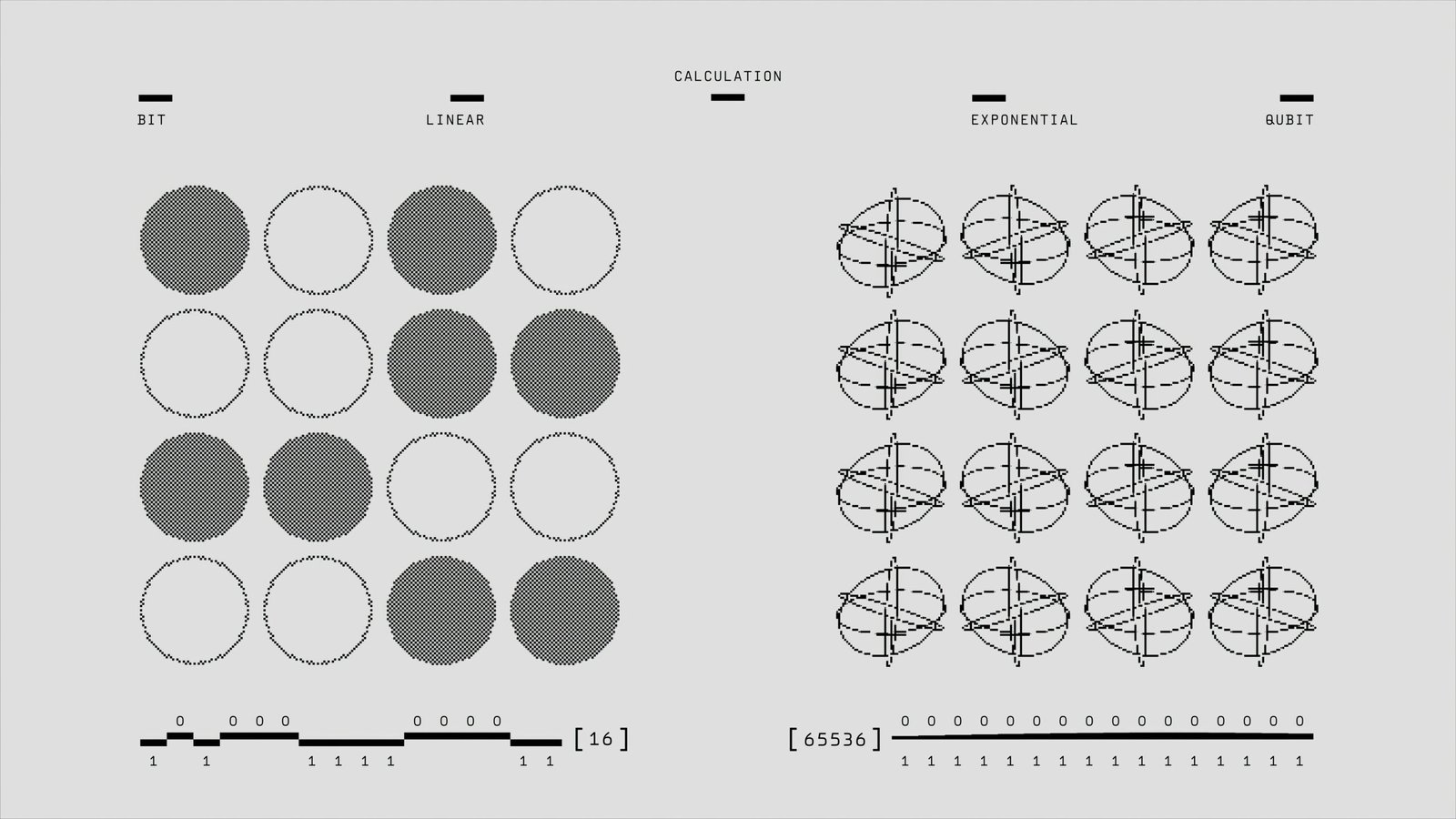

Finally, the complexity of designing printers for microgravity environments cannot be underestimated. Traditional 3D printers built for Earth’s gravity must be re-engineered to perform efficiently in space’s weightless conditions. This challenge involves extensive research and development to ensure these devices can produce consistent, reliable outputs without the benefit of gravity.

Future Prospects and Innovations in Space-based 3D Printing

The future of space-based 3D printing is a frontier teeming with unimaginable possibilities and profound implications for human endeavors beyond Earth. Emerging innovations are poised to enhance our ability to sustain long-term human presence on celestial bodies, such as the Moon and Mars. One of the most promising areas of research involves bioprinting, which focuses on creating biological materials for space medicine. This cutting-edge technology aims to address health challenges astronauts face in space, such as muscle atrophy and bone density loss, by enabling the in-situ production of essential tissues and medical implants.

Another visionary prospect is large-scale construction techniques for building sustainable habitats in space. Ongoing projects are investigating the use of indigenous materials like lunar regolith and Martian soil to reduce dependency on Earth-based resources. These techniques not only promise to make space colonization more feasible but also more economically viable. For instance, technologies such as sintering and direct energy deposition are being refined to construct large structures from local materials, offering pathways to create robust shelters that can withstand harsh cosmic environments.

Moreover, the collaborative efforts between international space agencies and private companies are accelerating the advancement of space-based 3D printing. Organizations like NASA, ESA, and private enterprises such as SpaceX and Blue Origin are collectively investing in research and development to push the boundaries of what is achievable. These partnerships not only drive technological innovations but also foster an ecosystem that encourages shared knowledge and resources, optimizing the potential for groundbreaking discoveries and applications.

In exploring the broader implications, the ability to print structures and tools in space directly influences our strategies for colonization and long-term habitation on other planets. It propels us closer to realizing self-sustaining outposts, where humans can live and work independently from Earth. This forward-looking approach highlights the transformative potential of 3D printing technology in reshaping our destiny across the solar system and beyond, inspiring humanity to envision a future where space is not just a destination, but a new domain for sustainable living.